Your design will dictate if we use the die struck process or the die cast process for manufacturing. There is typically three factors that help us decide to cast or stamp your order.

- Art

This topic is confusing to most of our customers. After all custom pins, medals and coins are 3D in nature. They have thickness and depth. However the thing the is the deciding factor is how the mold is engraved.

The vast majority of our products are made using the Die Struck process, rendered in 2D. The stamping comes out flat and will have two or three levels. You’ll notice that the stamping below is the same thickness and doesn’t have any protruding objects or curves to the base.

Visualizing your finished product is harder with 3D. We have to design it “flat” and then our factory takes over and uses AutoCad to extrude the design.

2) Desired Thickness And Size Of Your Product

Stamping presses are setup to handle items up to about 3″ and 2.5mm thick. So large, thick items can’t be manufactured easily by stamping.

If your product has a curve on the face of it or you want a 5″ wide medal, casting will be used.

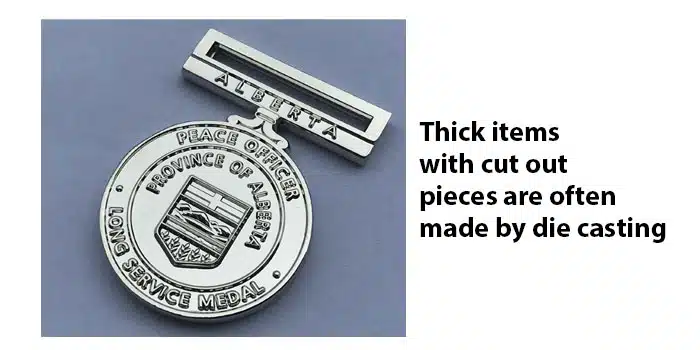

3) Does your product have openings or holes in it?

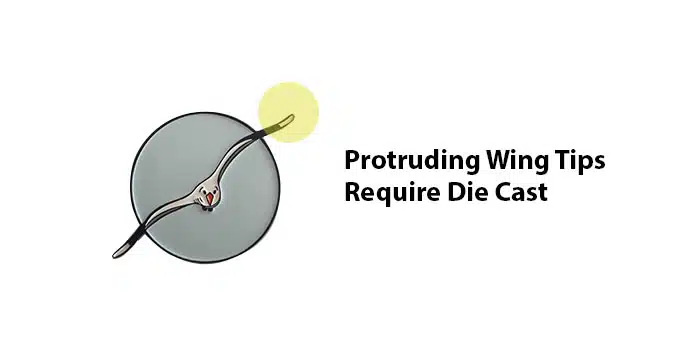

If we used the die struck process, adding cut out sections can be tricky or even impossible. We also choose cast when there are pointy or bigger protruding elements.

The pin itself is 2D.